The main sensors being explored for integration on the IMPACT chip are ISFET and Clark sensors for detection of pH and oxygen concentration.

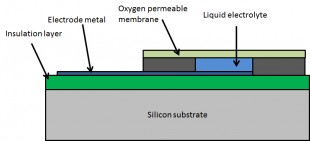

Electrochemical O2 sensor

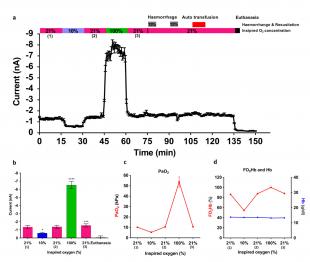

Oxygen can be easily measured by detecting its electrochemical reaction at a platinum electrode. This is the principle of the “Clark electrode” oxygen sensor, used for decades in scientific and medical research. The research challenges we undertook during the IMPACT programme were to miniaturise the Clark electrode for implantation, and adapt its architecture for microfabrication on silicon wafers.

The sensor we developed is fully solid-state, making it straightforward to manufacture and well optimised for use in an implantable medical device. It is integrated with an on-chip reference electrode to create a self-contained sensor system. This work involved development of designs and processing methods for novel materials [1], and comprehensive sensor performance testing both on the bench and in vivo [2, 3].

Our technology can be directly transferred to silicon wafers containing the electronics that drive the sensor and exchange data and power with the external environment. This next step will create a smart sensor for reading out hypoxia in tumours, and a wide range of other medical applications.

ISFET pH sensor

The Ion Sensitive Field Effect Transistor (ISFET) is an advanced pH sensitive semiconductor device. It is based on a modified version of the standard MOSFET – the basic transistor used throughout modern microelectronic devices. In the ISFET the transistor gate connection is controlled by surface charge that is set by pH in the solution it contacts, rather than a conventional electrical connection.

Our ISFETs are made using industry-standard CMOS microfabrication processes at a commercial semiconductor foundry. They take advantage of the standard CMOS metallisation layers to bring the gate connection up to the surface of the chip. This makes them ideally suited for integration with on-chip instrumentation [4].

We have also developed specialised methods for “post-processing” these foundry devices to improve their sensitivity to pH, and to add an on-chip reference electrode. These techniques are broadly applicable to other areas where additional functionality can be added to foundry devices.

Circuit design

The defining characteristic of a smart sensor is its on-board electronic circuits for sensor interfacing and signal processing. We have designed circuits that are optimised for operating with electrochemical sensors (e.g. a miniature potentiostat), and implemented them using standard CMOS technologies [5]. We also explored circuits for wireless power and communications – these will be crucial for autonomous operation of the implanted sensors.

Sensor packaging

Deploying miniature sensors and electronics in the body requires a fine balance of protection from the environment, while allowing sufficient direct access to allow operation.

We have developed a novel encapsulation technique that meets these needs. It uses photocurable epoxy to seal the sensor chip electronics, except where required at the sensing areas [6]. The encapsulation is thin to minimise the final device dimensions, and durable enough to function as a stable barrier over a course of treatment. The packaging uses only certified biocompatible materials, and we have demonstrated its robustness during tumour implantation procedures.

Data and signal processing

The aim of IMPACT is to personalise the delivery of radiotherapy and to monitor its effect using implantable sensors. The data and signal processing strand focused on analysis methods for the sensor outputs, and how they can be used to adapt cancer treatment to the individual patient.

By analysing how these key parameters (oxygen, pH, biomarkers) interact and vary within the tumour and evolve during the treatment, we will be able to interpret the measured signals from which useful information can be extracted. As a consequence, this project will provide powerful tools enabling the patient treatment to be assessed and adapted if required (i.e. number and frequency of radiotherapy fractions) and thus improve patient outcome.

References

1. Marland, J.R.K. et al. (2020) Optimization of Nafion Polymer Electrolyte Membrane Design and Microfabrication. IEEE Transactions on Semiconductor Manufacturing 33 (2), 196-201.

2. Marland, J.R.K. et al. (2020) Real-time measurement of tumour hypoxia using an implantable microfabricated oxygen sensor. engrXiv doi:10.31224/osf.io/fhqd7.

3. Gray, M.E. et al. (2019) In Vivo Validation of a Miniaturised Electrochemical Oxygen Sensor for Measuring Intestinal Oxygen Tension. American Journal of Physiology-Gastrointestinal and Liver Physiology 317, 242-252.

4. Marland, J.R.K. et al. (2018) Implantable Microsystems for Personalised Anticancer Therapy. CMOS Circuits for Biological Sensing and Processing, 259-286.

5. Gunasekaran, C. et al., CMOS current attenuator for electrochemical sensing applications, 2017 Ieee Sensors, 2017, pp. 1-3.

6. Blair, E.O. et al. (2020) Test Structures for Developing Packaging for Implantable Sensors. IEEE Transactions on Semiconductor Manufacturing 33 (2), 224-231.